Excel Automation for Manufacturers: Smarter, Faster and AI-Ready

Manufacturers rely on Excel every day, but with custom programming, it can do far more than spreadsheets. Automate tasks, reduce errors, and build tailored tools that streamline production, reporting, and planning. Discover how AI enhanced Excel programming modernizes workflows and helps manufacturers like Maysteel save time and scale with confidence.

- Helps reduce manual tasks, errors, and delays in production workflows.

- Enables real-time reporting, system integration, and custom dashboards.

- Excel Help delivers custom excel programming solutions

Picture This: Your team on the factory floor, scanning sheets of paper, entering data into Excel, copying and pasting between tabs day in, day out. It works…mostly. But what if you could automate all that? Imagine a system that pulls in production data, recalculates key metrics instantly, flags issues in real time, and even sends summary reports without anyone typing a single cell manually.

That’s the power of Excel programming: taking your familiar tool, Excel, and turning it into a lean, automated engine that plugs right into your manufacturing processes.

Here we’ll walk you through how Excel programming goes beyond basic spreadsheets to streamline your workflows, eliminate errors, and free your team to focus on what matters most: innovation, safety, and production quality.

What is Excel Programming for Manufacturing?

Excel programming means using Visual Basic for Applications (VBA), SQL integrations, Python scripting, and custom add‑ins to automate and enhance Excel beyond formulas alone. It’s far more than just a spreadsheet; it becomes an automated workflow engine that can:

- Import production-line data directly from databases or machines (e.g., CSVs, SQL, IoT endpoints).

- Clean, transform, and analyze data automatically.

- Trigger alerts for downtime, quality issues, or maintenance needs.

- Generate standardized reports and dashboards with the click of a button.

At Excel Help, with our Excel programming services clients experience a staggering 250% increase in efficiency per project, coupled with a reduction in overhead costs of 20-40%. We bring factory workflows into Excel and turn them into reliable, repeatable processes.

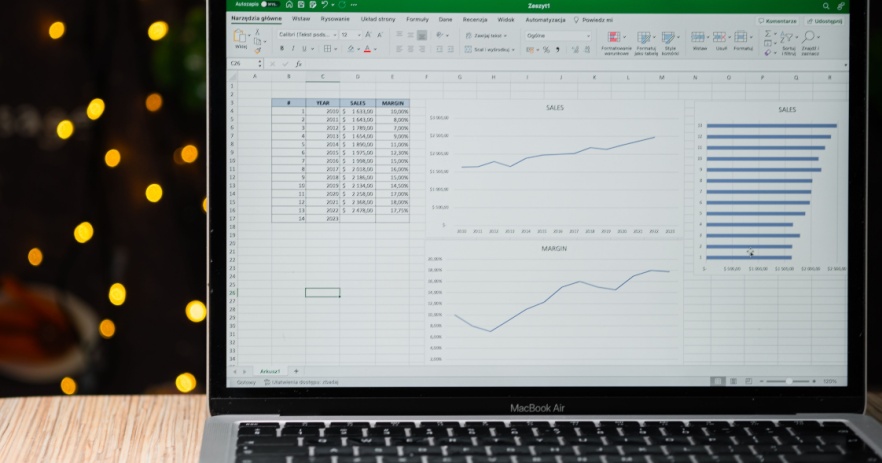

What Does Programming in Excel Look Like?

If you’ve ever wondered what programming with Excel looks like, it starts with understanding what your workflows require and then building smart automations to match. You might use VBA to automate part rejection tracking, write SQL queries to import raw production data, or develop a custom dashboard that updates in real time.

Whether you want to program in Excel yourself or partner with experts to handle it for you, the goal is the same: eliminate bottlenecks, reduce errors, and let Excel do the heavy lifting.

Want to learn more about how to program in Excel yourself? Check out our Excel training programs. Learn everything you need to know about getting the most out of your Microsoft office programs.

Why It Matters for Manufacturing Workflows

Manufacturing environments depend on consistent, accurate, and timely data to drive decision-making. Manual spreadsheet workflows are vulnerable to:

- Typing errors and formula mistakes, which multiply risk.

- Analysis delays, leading to production hold-ups.

- Redundant tasks that waste resources and personnel time.

Excel programming builds automations that eliminate manual handling and offer:

- Near-zero data errors. Custom scripts follow defined logic every time.

- Real-time insights, like flagging part rejects or maintenance windows.

- Highly efficient workflows. Automation means faster analysis and happier teams.

How Excel Help Delivers Tailored Excel Automations

We do more than just write code; we design Excel solutions that mirror how your business actually runs in the real world. Whether you’re managing production line data, financial reports, or quality metrics, here’s how we help:

Automations That Save Hours

We turn time-consuming tasks into single-click operations using Excel macros, custom scripts, and automation logic. Whether it’s pulling production data or generating reports, what once took hours can now happen in seconds.

Integrated Data Systems

Connect Excel to your full data ecosystem including SQL, Oracle, .CSV files, and more. We design solutions that pull live data into Excel automatically, keeping everything up to date and accurate without manual input.

Dashboards & Reporting You Can Trust

We build clean, interactive dashboards that highlight key metrics, trends, and alerts at a glance. From quality control summaries to executive-level financial forecasting, your data is always clear, structured, and decision-ready.

Interfaces Built for Your Workflow

Custom navigation menus, smart data entry forms, and multi-user Excel/Access applications make it easy for your team to interact with the tools—no confusion, just results.

Advanced Analytics & Visuals

From data mining and segmentation to custom-built charts and performance visuals, we help you uncover patterns, spot bottlenecks, and track performance in ways spreadsheets alone just can’t.

In short, we turn Excel into an intelligent manufacturing platform that’s fully automated, easy to use, and tailored to how your business operates.

Client Spotlight: Maysteel Transforms Manufacturing Process with Excel Programming

One example of programming in Excel at scale comes from Maysteel, a leading U.S. sheet metal manufacturer. Faced with a complex system of job costing, pricing, and scheduling across multiple departments, they needed a unified, scalable solution.

We developed a centralized Excel front-end powered by a SQL Azure back-end that replaced Maysteel’s manual documentation process with a flexible, automated system. Sales engineers now navigate their Bill of Materials, purchase summaries, and customer quotes from a single Excel-based interface complete with Active-X controls and zero need for additional code.

The result? Lower costs, simplified processes, and a system built to grow with their business, all using tools their team already knew.

Getting Started: The Excel Help Advantage

Bringing automation into your manufacturing operations doesn’t need to be disruptive, it just needs to be strategic. Here’s how we make it easy:

- Strategic Planning: We start with a free consultation to deeply understand your processes, pain points, and goals. From there, we move to your custom roadmap to target the highest-impact areas first.

- Roadmap Engagement: Just as any architect develops plans to build a house, our Excel Roadmap team will gather requirements through 2-3 meetings and develop specific plans and mockups for the Excel and/or Database solution.

- Remote Development: Our expert developers build your solution off-site, ensuring minimal interruption to your daily operations. Whether it’s building dashboards, automating reports, or integrating live data, everything is tailored to your workflow.

- Empowering Your Team: After launch, we provide thorough support & training so your staff can confidently use and maintain the new tools. You won’t just get a smarter system; you’ll have a team that knows how to use it.

Ready to reduce errors, speed up processes, and turn Excel into a powerful automation engine for your manufacturing team?

Schedule your free consultation today and let’s start building your custom solution.